- You have no items in your shopping cart

- Continue Shopping

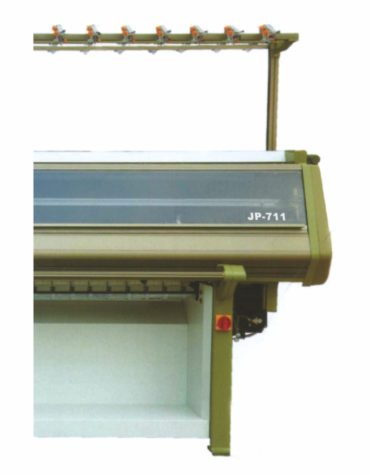

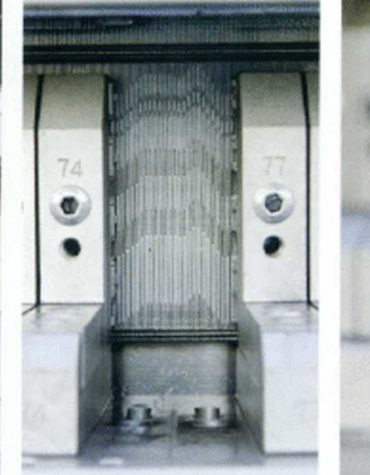

Mini Jacquard Collar Machine JP602

$1,000.00

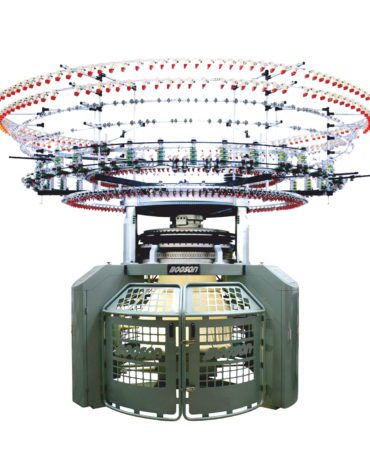

Achieve productivity in the production area with the new generation knitting machine. It allows you to save time in production with its easy usage and performance. With its superior performance and quality production capability, it makes a distant distinction between its counterparts. With this machine you can produce quality and unique products.

Our company stands in the back of our products with regard to customer satisfaction in terms of spare parts supply and technical support service.

Mini Jacquard Collar Machine JP602

Control Board

The machine computer operating system is specially designed by Boosan engineer. Boosan has spent years trying to make the operating system more user-friendly and more stable than ever before. There is a USB socket under the control keyboard, the user can save multiple mesh designs to an external disk.

Precision Shuttle

The new shuttle system is more robust and lighter than ever before.

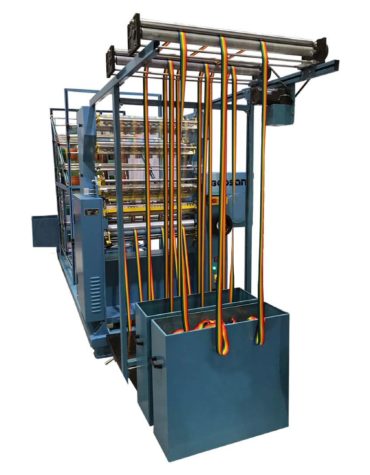

Shuttle System

The 24-ball bearing structure design ensures long life for the shuttle.

Thread Feeder

The thread feeders are made of special steel with threads, which effectively reduce the broken thread and ensure the thread ends smoothly. Single steel system, nopen and mesh system on front and back plate, double sided, striped etc. can make patterns.

New Design Arbor

New electronic gazebos that can be easily threaded inside.

| Weight | 793 kg |

|---|---|

| Dimensions | 2720 × 1880 × 850 mm |

| Production Capacity | |

| Supply Capacity | |

| Cam System | |

| Feeder | |

| Stitch Density | |

| Gauge | |

| Knitting Width | |

| Knitting Speed | |

| Racking | |

| Roller | |

| Control System | The carriage is driven and controlled by the Boosan operation system |

| Automatic Intervention | Cam motor error, Fabric drop, Fabric end, Jacquard error, Knot, Motor overload, Motor setting error, Needle break, Side feeder |

| Power |