- You have no items in your shopping cart

- Continue Shopping

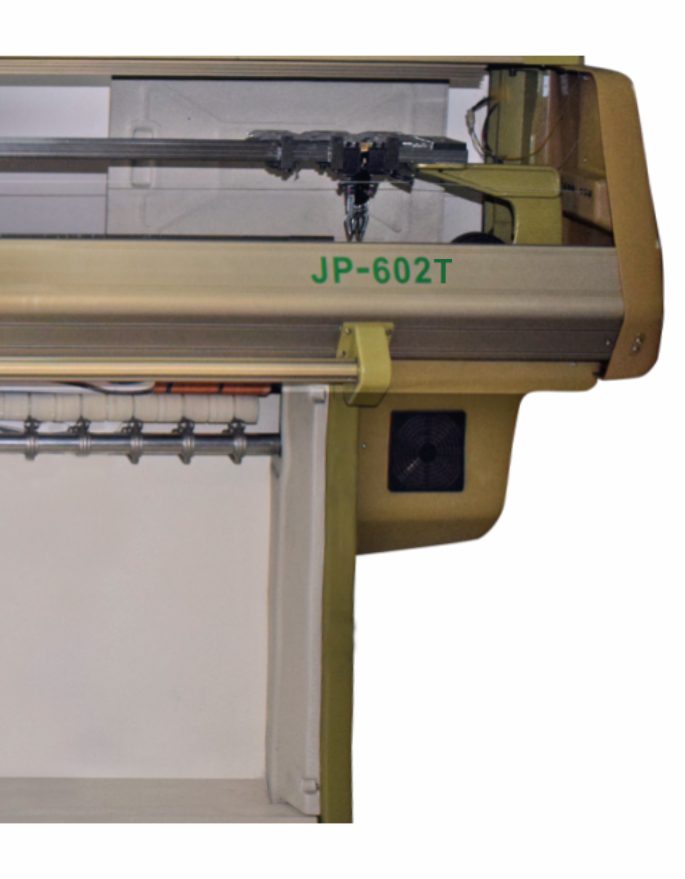

Mini Jacquard Collar Machine (Transfer) JP602T

$1,000.00

About Collar Machine

We provide 24/7 Technical Service and Spare Parts for our Santeks Textile Machinery, Collar Machine products. We also offer you technical support in this sense so that you can produce your machines without any problems with our professional technical service staff. With its wide spare parts network, we provide spare parts with domestic and international cargo.

The products that JP-602T Transfer Mini Jacquard Collar Machine can do are as follows;

It has the feature of transferring from the front plate to the back plate, the feature of making simple patterns with platinum support, the feature of making collars such as eyelet, square, camisole, cuff polo collar.

[vc_row][vc_column][vc_column_text]

Mini Jacquard Collar Machine with Transfer Transfer JP-602T

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_row_inner][vc_column_inner width=”1/4″][vc_icon icon_fontawesome=”fas fa-chevron-circle-right” size=”xl” align=”right”][/vc_column_inner][vc_column_inner width=”3/4″][vc_column_text]

Control Panel

The machine computer operating system is specially designed by Boosan engineer. Boosan has spent years trying to make the operating system more user-friendly and more stable than ever before. There is a USB socket under the control keyboard, the user can save multiple mesh designs to an external disk.[/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_column][vc_column width=”1/2″][vc_row_inner][vc_column_inner width=”1/4″][vc_icon icon_fontawesome=”fas fa-chevron-circle-right” size=”xl” align=”right”][/vc_column_inner][vc_column_inner width=”3/4″][vc_column_text]

Thread Feeder

The thread feeders are made of special steel with threads, which effectively reduce the broken thread and ensure the thread ends smoothly. Single steel system, nopen and mesh system on front and back plate, double side, striped etc. can make patterns.[/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_row_inner][vc_column_inner width=”1/4″][vc_icon icon_fontawesome=”fas fa-chevron-circle-right” size=”xl” align=”right”][/vc_column_inner][vc_column_inner width=”3/4″][vc_column_text]

Shuttle System

It has the ability to use 6 shuttles on 3 rails. It allows you to produce high performance without any problems with its quality material.[/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_column][vc_column width=”1/2″][vc_row_inner][vc_column_inner width=”1/4″][vc_icon icon_fontawesome=”fas fa-chevron-circle-right” size=”xl” align=”right”][/vc_column_inner][vc_column_inner width=”3/4″][vc_column_text]

Precision Shuttle

The new shuttle system is more robust and lighter than ever before.[/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row]

| Weight | 800 kg |

|---|---|

| Dimensions | 2720 × 1880 × 900 mm |

| Üretim Kapasitesi | |

| Tedarik Yeteneği | |

| Çelik Sistem | |

| Besleyici / Mekik | |

| Dikiş Yoğunluğu | |

| İncelik | |

| Örgü Genişliği | |

| Örgü Hızı | |

| Yan Gergi | |

| Silindir | |

| Kontrol Sistemi | The carriage is driven and controlled by the Boosan operation system |

| Otomatik Müdahale | Cam motor error, Fabric drop, Fabric end, Jacquard error, Knot, Motor overload, Motor setting error, Needle break, Side feeder |

| Güç |