- You have no items in your shopping cart

- Continue Shopping

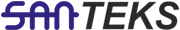

Computerized Full Jacquard Knitting Collar Machine JP712

$1,000.00

Achieve productivity in the production area with the new generation knitting machine. It allows you to save time in production with its easy usage and performance. With its superior performance and quality production capability, it makes a distant distinction between its counterparts. With this machine you can produce quality and unique products.

Our company stands in the back of our products with regard to customer satisfaction in terms of spare parts supply and technical support service.

Computerized Full Jacquard Knitting Collar Machine JP712

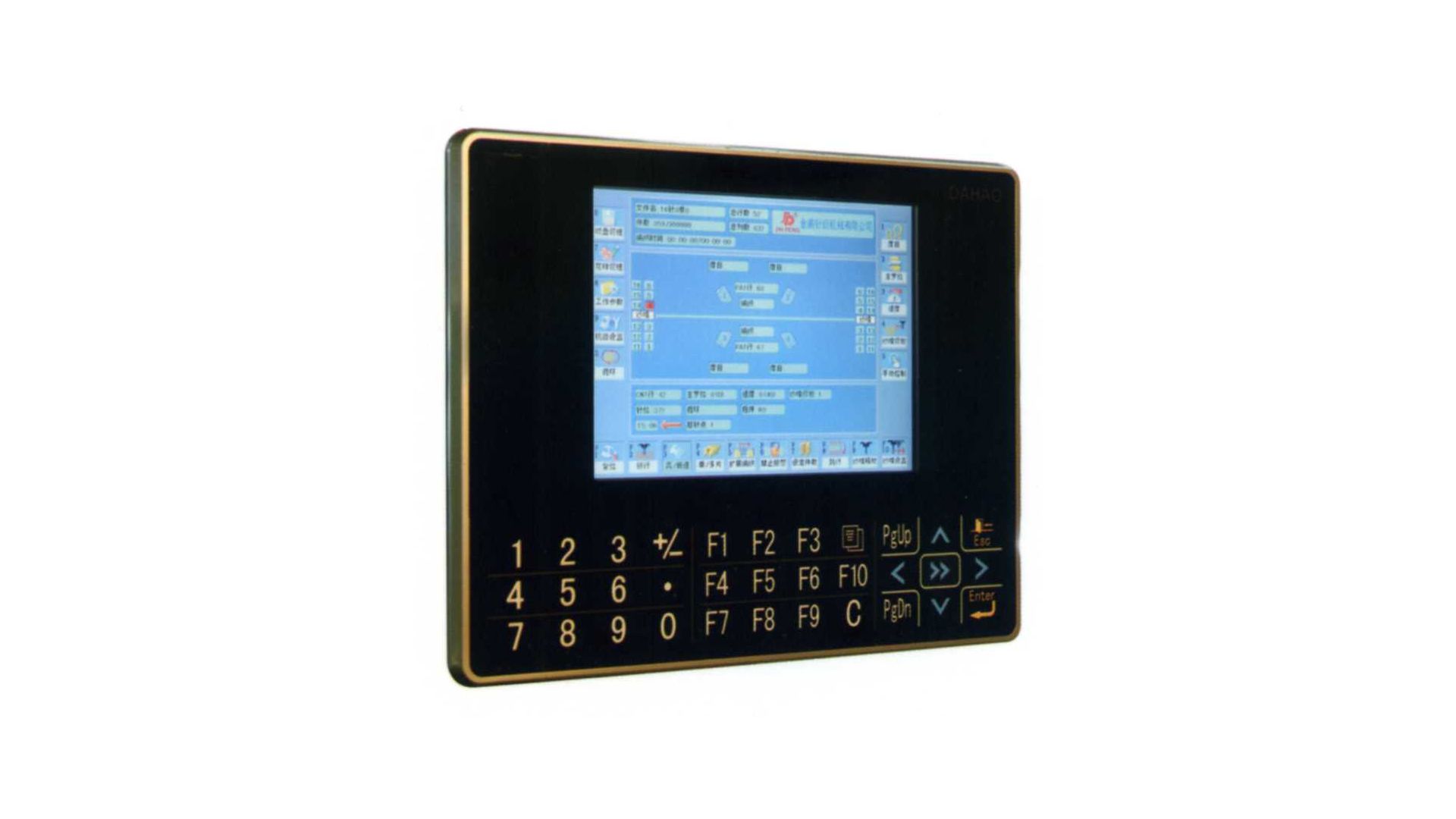

Control Board

Visual touchscreen interface showing knitting movement. It is easy for the employee to change the data setting. Designs can be stored or transferred from USB disk. The quick edit function is useful for a new operator. New safety doors and emergency protection increase operator safety.

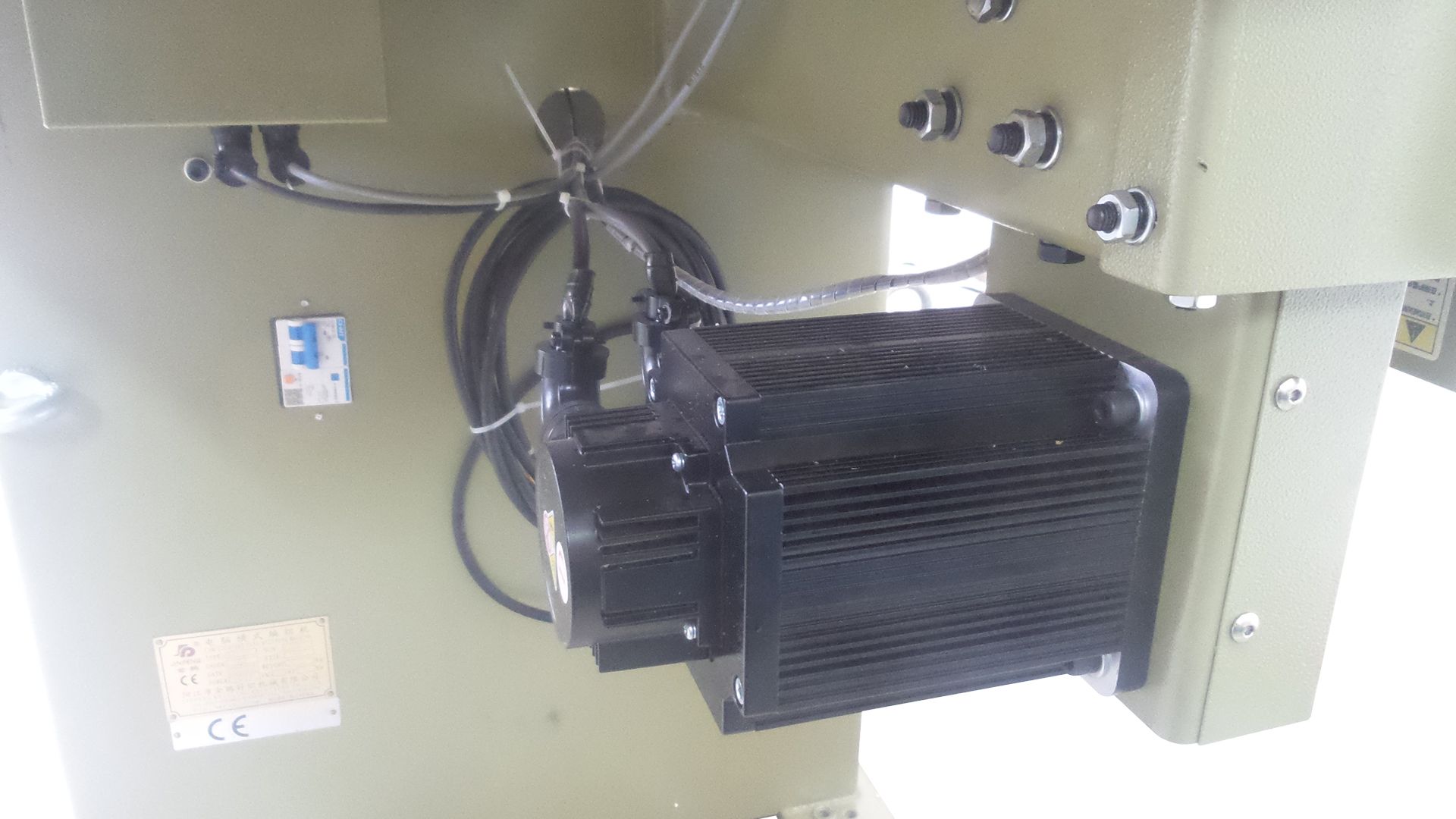

Servo-motor

Machine head and rack bed are working with servo motor, working parameter data can be adjusted according to working conditions. Machine head movement, servo quick direction change control and motion technique have been improved, it is 10% faster than the old type machine.

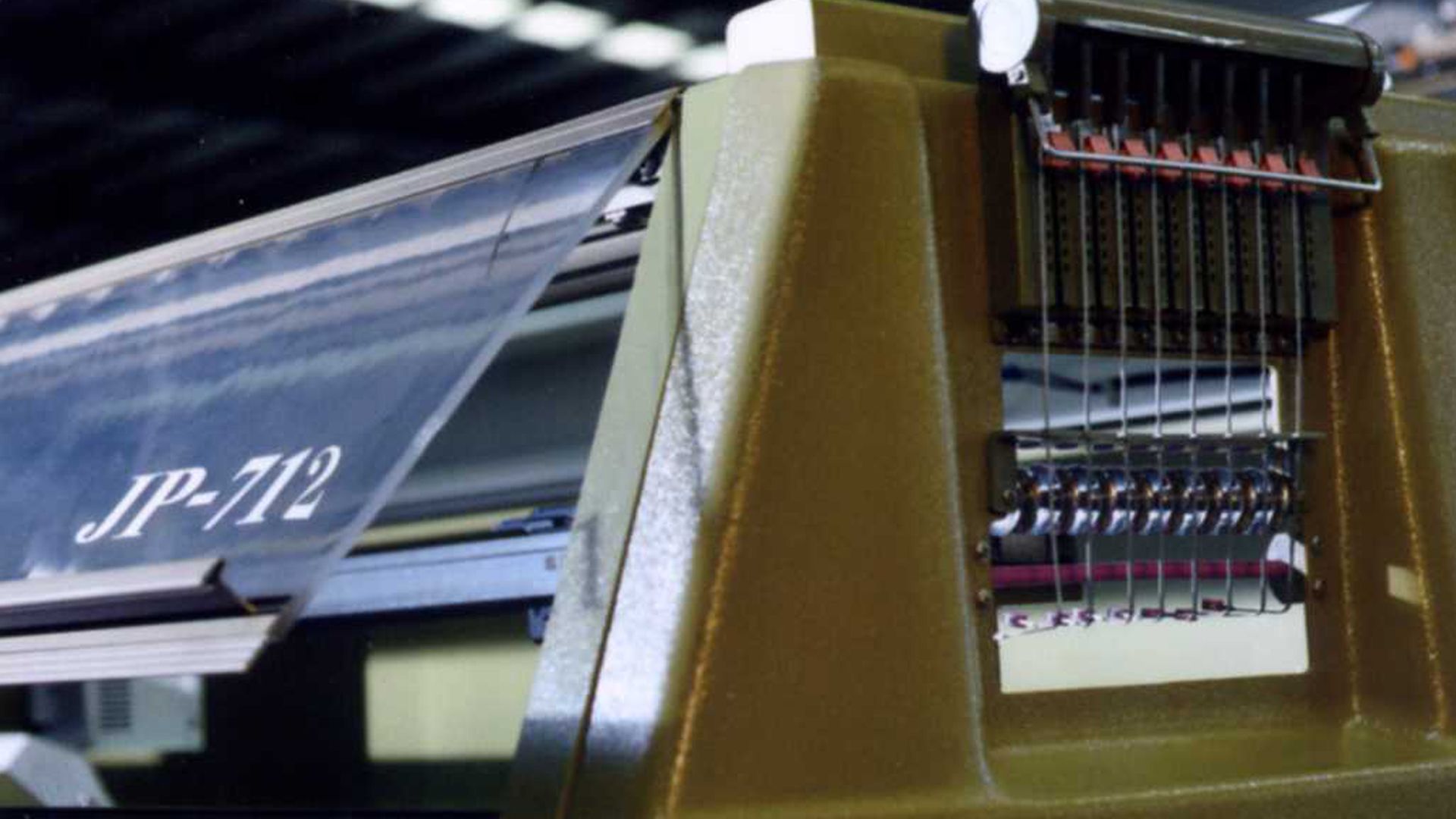

New design

New design safe side covers and gazebos.

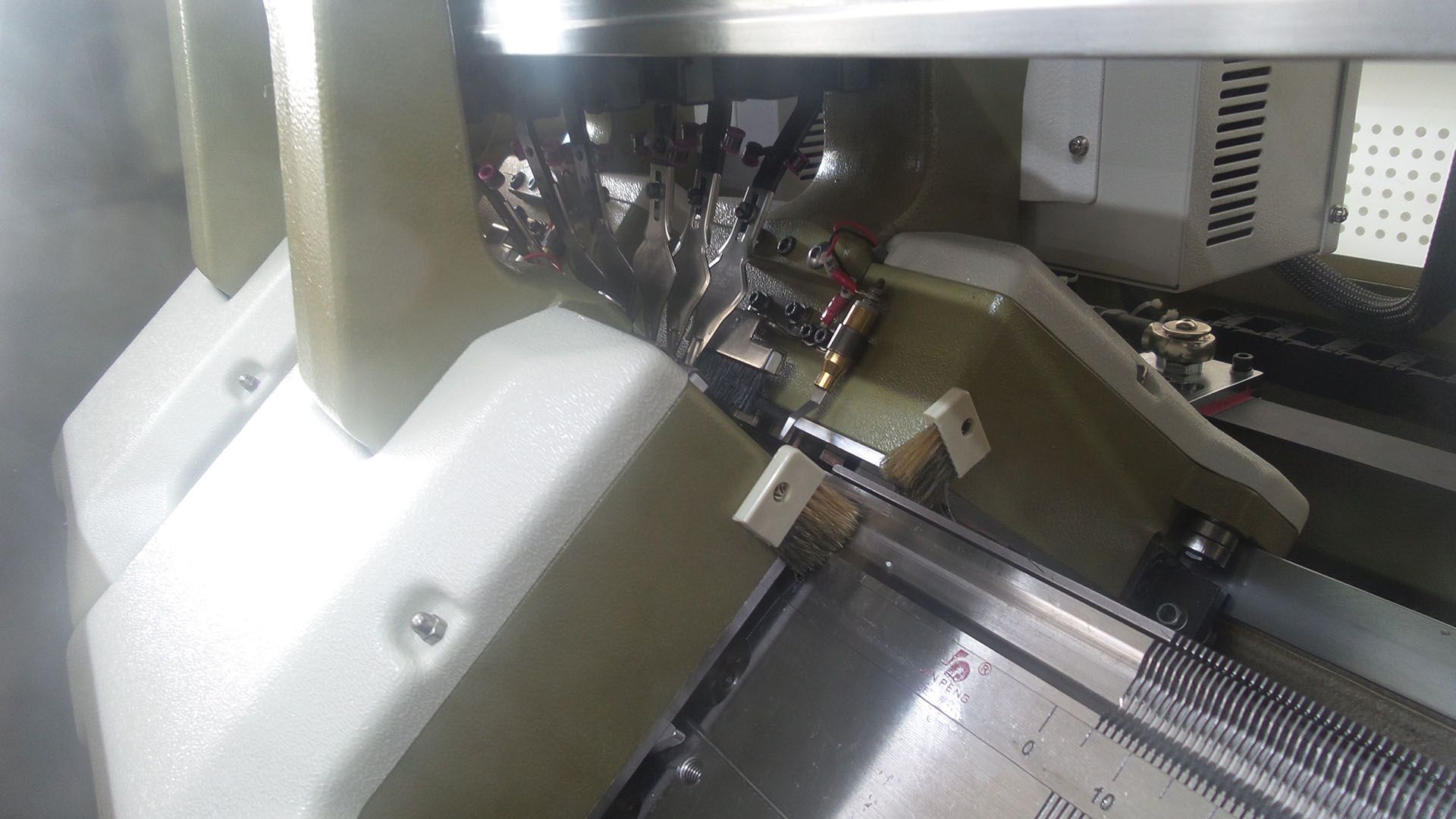

Steel System

712 cam system can make basic full jacquard and intarsia structure fabric. 8 sets of solen old needle selection structure.

New Type Upper Arbor

The upper arbor has been developed for easier threading.

| Weight | 925 kg |

|---|---|

| Dimensions | 3625 × 1800 × 840 mm |

| Production Capacity | |

| Supply Capacity | |

| Cam System | Single carriage and 3 system, 8 needle jack full jackuard selection cams |

| Feeder | |

| Stitch Density | |

| Gauge | |

| Knitting Width | |

| Knitting Speed | Max. 1.5m/s depending on knitting wide and knitting material. 32 sets of speed control |

| Racking | |

| Roller | 32 sets of roller control, each set from level 0~100 adjustable |

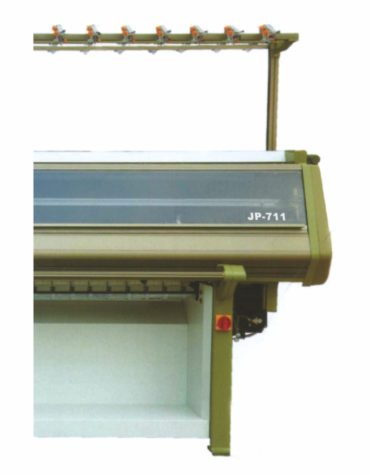

| Control System | The carriage is driven and controlled by the Boosan operation system |

| Automatic Intervention | Cam motor error, Fabric drop, Fabric end, Jacquard error, Knot, Motor overload, Motor setting error, Needle break, Side feeder |

| Power |